Monitoring coating processes in vacuum chambers

Monitoring coating processes

in vacuum chambers - Controllo di processi in vuoto

Monitoring coating processes in vacuum chambers

Important parameters that need to be monitored during coating processes, such as layer thickness, composition, surface finish, light transmission, reflectance, polarization ability, and others, can be done by spectroscopy and spectroscopic interferometry. Fiber optics provide a versatile tool to take light in and out of the remote vacuum and clean room chambers and at the same time organize the select measurement geometry for the coating analysis. The illumination of and detection from the coating layering can be organized at different fiber positions relative to the coating; to allow specular reflection, diffuse reflection, transmission, polarization, interference, fluorescence and even Raman scattering to be measured. The fiber optics can be arranged to monitor several parameters simultaneously or to measure at different spatial positions or masking conditions simultaneously.

For on-line production several fiber optic sensors with suitable geometries can be placed across the web to monitor the production run. In some cases the ionic source; for example a plasma source, can be monitored for spectral emission to confirm its conditional efficiency during the operating process.

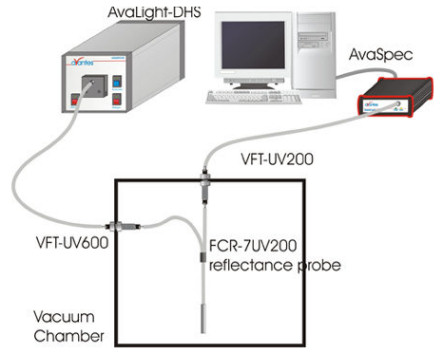

A typical setup for vacuum measurements is given below:

Components used in the vacuum measurement setup are depicted in the following table:

Spectrometer |

AvaSpec- 2048 |

Grating UA (200-1100nm), 50µm slit , UV coating, DCL-UV, OSC |

|

Software |

AvaSoft-Full and XLS or PROC add-on |

Lightsource |

AvaLight-DH-S deuterium-halogen light source |

Fiber optics |

FCR-7UV200-2-ME reflection probe UV/VIS, 2m, SMA |

Vacuum Feedthrough |

FC-VFT-UV200 and FC-VFT-UV600 |

Home | Prodotti | Lista rappresentate | Modulo Informazioni | News | Contatti